top of page

SEW PROCESSING

SOLUTION OVERVIEW

For Heating

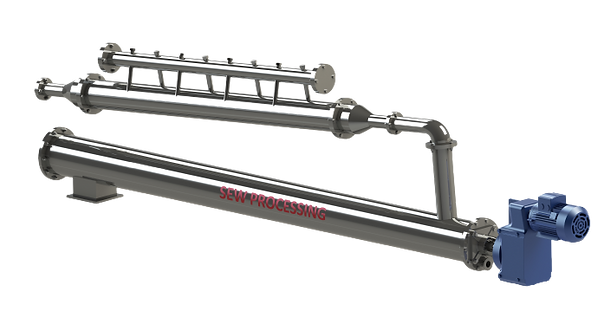

In every rendering process there is need of a specific type of cooking or heating equipment to ensure the correct transfer of heat to products. SEW provides tailor-made solutions for all types of raw material in various parts of different processes.

The SEW Batch Cooker are used for cooking, hydrolysis, sterilization, and drying of any raw material of animal origin. The method consists in the heat exchange that takes place from the contact between the product and the heated surfaces inside the equipment. An efficient purge system eliminates the condensate inside the shaft, ensuring maximum equipment efficiency. The Batch Cooker may be manufactured in models with and without pressure inside the body, fulfilling the most stringent international standards.

THE AVAILABLE EQUIPMENTS

bottom of page